PVC Flexible Metsi Bladder Bag

PVC Flexible Metsi Bladder Bag

Tlhahisoleseding ya Sehlahiswa

Mokotla oa mokelikeli o entsoe ka lesela le tenyetsehang la PVC. Mekotla ea metsi e na le matla a phahameng a khatello le ts'ebetso e ntle ea ho tiisa, 'me e sebelisoa haholo liindastering tse fapaneng bakeng sa tlhahiso le bophelo ba letsatsi le letsatsi.

Ponelopele e na le boiphihlelo ba lilemo tse fetang 15 tlhahisong ea masela, ka tlhahiso ea selemo le selemo ea lisekoere-mithara tse fetang limilione tse 5. Ka nako e ts'oanang, re na le mechini e tsoetseng pele ea maqhubu a holimo, metjhini ea ho tjheseletsa ea mofuta oa C, theknoloji ea tjheseletsa ea masela, lihlopha tsa ho lokisa lihlahisoa tse felileng, lithupelo tse hloekileng le tse sephara tse se nang lerōle, mekhoa e ke keng ea bapisoa, lebelo la ho sebetsa le bokhoni ba ho fana ka litšebeletso tse fanang ka lits'ebeletso tse emisang ho etsoa ha mekotla ea metsi ka boleng bo tsitsitseng le ho lokisa lihlahisoa tse felileng bakeng sa bareki ba lapeng le kantle ho naha.

Parameter ea lihlahisoa

| Tlhaloso ea Teknoloji ea Mokotla oa Metsi | ||||||

| Ntho | Yuniti | Mohlala | Maemo a Phethahatso | |||

| ZQ70 | ZQ90 | ZQ120 | SCYY90 | |||

| Lesela la motheo | - | PES | - | |||

| Mmala | - | Seretse se sefubelu, Boputsoa, Botala ba sesole, Bosoeu | - | |||

| Botenya | mm | 0.7 | 0.9 | 1.2 | 0.9 | - |

| Bophara | mm | 2100 | 2100 | 2100 | 2100 | - |

| Matla a tiileng (warp/weft) | N/5cm | 2700/2550 | 3500/3400 | 3800/3700 | 4500/4300 | DIN 53354 |

| Matla a ho tabola (warp/weft) | N | 350/300 | 450/400 | 550/450 | 420/410 | DIN53363 |

| Matla a ho khomarela | N/5cm | 100 | 100 | 120 | 100 | DIN53357 |

| Tšireletso ea UV | - | Ee | - | |||

| Threshold Temperature | ℃ | -30-70 | DIN EN 1876-2 | |||

| Acid le alkali corrosion resistance | 672h | Ponahalo | ha ho na makhopho, mapetsong, delamination le masoba | FZ/T01008-2008 | ||

| Sekhahla sa ho boloka boima ba 'mele | ≥90% | |||||

| Ho hanyetsa serame (-25 ℃) | Ha ho mapetsong holim'a metsi | |||||

| Lintlha tse ka holimo ke karolelano ea litšupiso, tse lumellang 10% mamello. Ho itloaetsa hoa amoheleha bakeng sa litekanyetso tsohle tse fanoeng. | ||||||

Sehlahisoa Tšobotsi

◈ Ts'ebetso e ntle ea ho thibela metsi

◈ Botsitso bo phahameng le bo tlase ba mocheso

◈ Ho thibela boemo ba leholimo

◈ Ho tenyetseha, libopeho tse ikhethileng, le boholo lia amoheleha

◈ Ho bonolo ho menaha, ho paka, le ho tsamaisoa

◈ Ho kenya habonolo le ts'ebetso e bonolo

◈ Tšireletso ea tikoloho 'me ha ho na tšilafalo

Molemo oa Sehlahisoa

Ho feta lilemo tse 15 tsa boiphihlelo ho hlahisoeng ha masela le lesela la PVC, sehlopha se matla sa lipatlisiso tsa mahlale, basebetsi ba fetang 10 ba boenjiniere le botekgeniki ba nang le li-degree tsa koleche tse profeshenale, lisebelisoa tse fetang 30 tsa lebelo le phahameng, likhoele tse tharo tsa tlhahiso tse nang le tlhahiso ea selemo le selemo ea lithane tse fetang 10,000 tsa li-membrane tsa calendered, le lithapo tse tharo tsa tlhahiso ea selemo le selemo tsa lisekoere tse limilione tse 5. lesela, fana ka tšehetso ea nako e telele le litšebeletso bakeng sa balateli khampani le merero e meholo lapeng le linaheng tse ling.

Mechini e tsoetseng pele e tsoetseng pele ea orbital, mochini oa ho tjheseletsa oa mofuta oa C, theknoloji ea ho tjheseletsa masela, lihlopha tse felileng tsa ho lokisa lihlahisoa, le lithupelo tse hloekileng, tse se nang lerole kaofela li teng.

Sebopeho le boholo ba mokotla oa metsi o hlophisitsoeng, hammoho le 'mala, lia amoheleha.

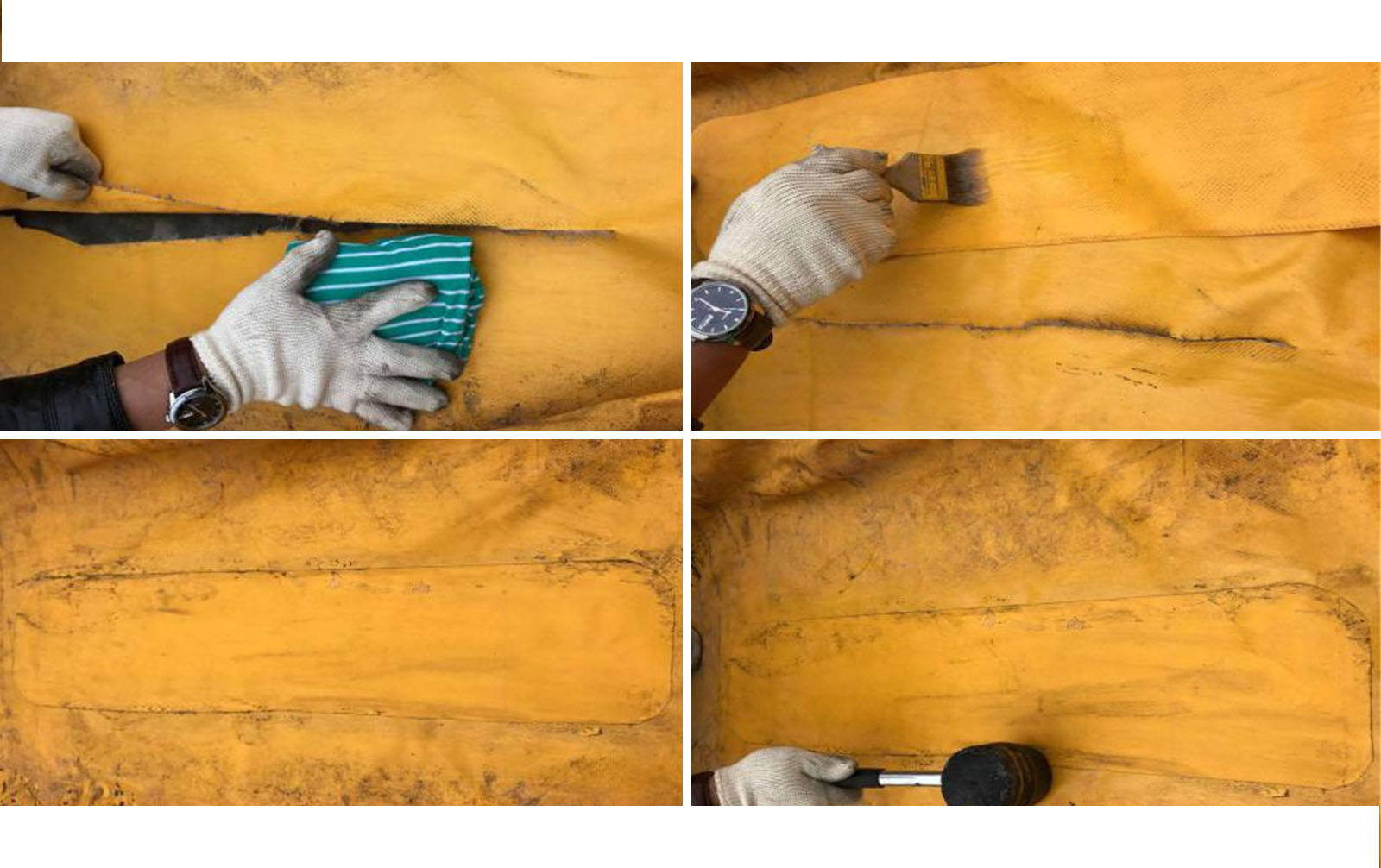

Sekhomaretsi le sethunya sa moea se chesang se nkehang habobebe ke mekhoa e 'meli e fapaneng ea ho lokisa.

Pallet e pakang e tla etsoa ho latela palo ea odara le boholo ba setshelo, ho leka ho boloka litšenyehelo tsa lipalangoang.

Kopo

E kenya mokotla oa metsi oa teko

Mokotla oa ho belisoa ha biogas

Mokotla oa ho boloka metsi a nosetso

Mokotla oa pokello ea metsi a pula