Anti-seepage Pond Liner Fabric

Anti-seepage Pond Liner Fabric

Tlhahisoleseding ya Sehlahiswa

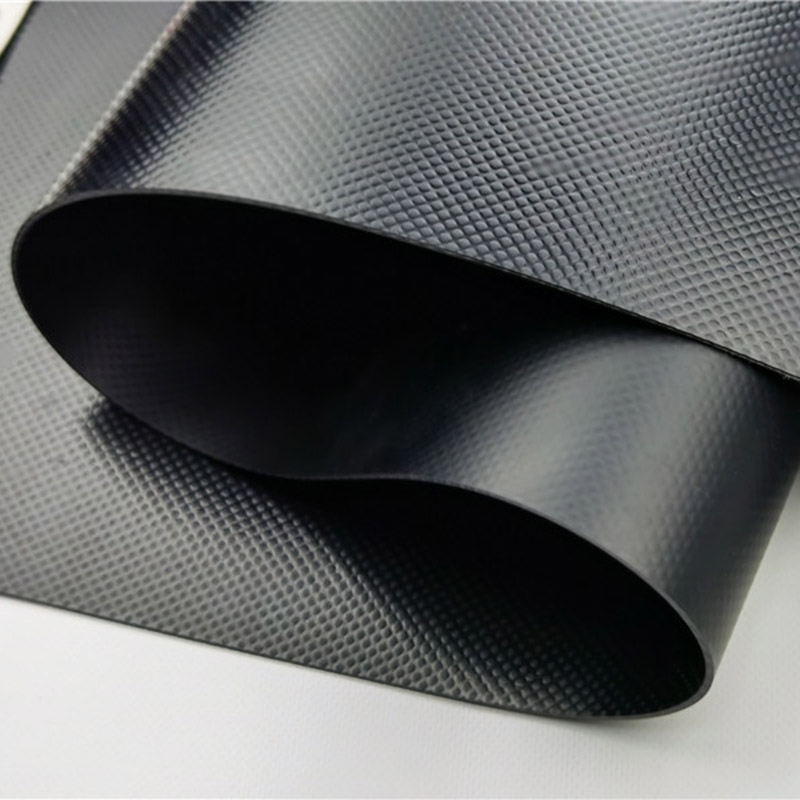

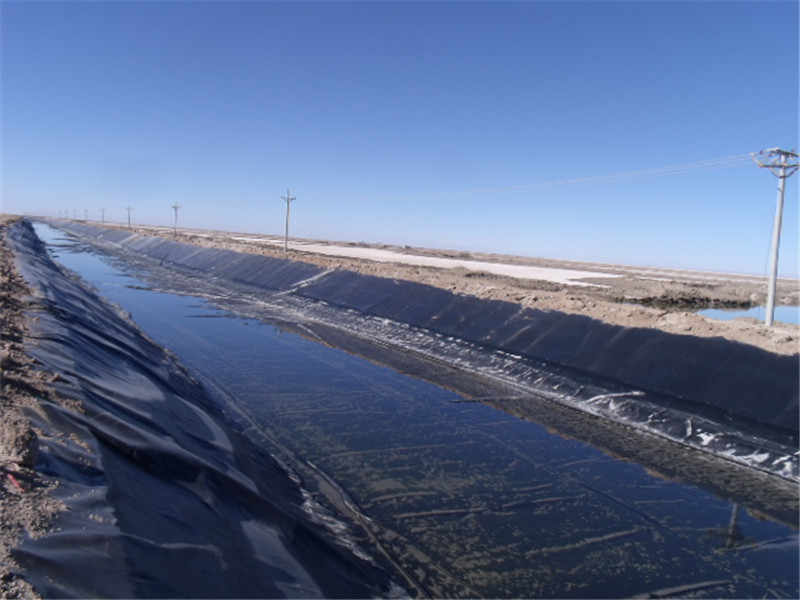

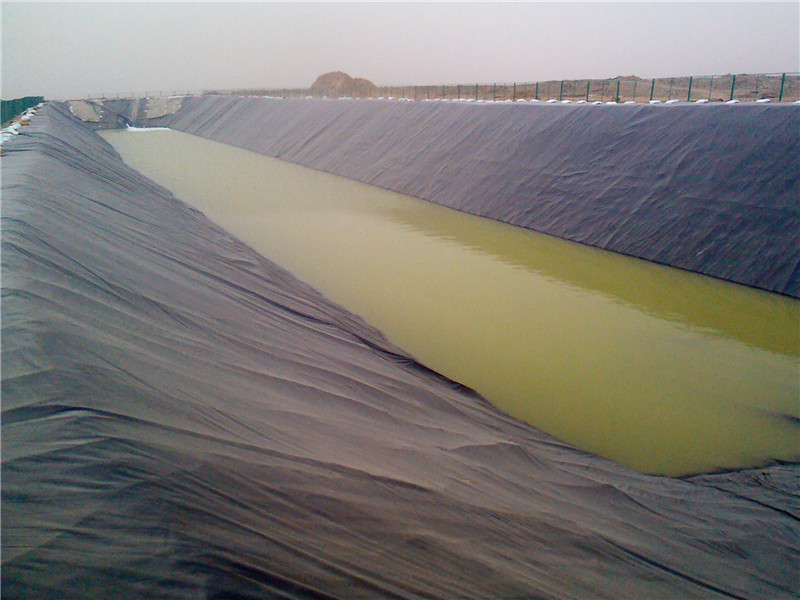

Lesela la PVC le khahlanong le seepage le entsoe ka fiber e matla e phahameng ea polyester e nang le lesela la PVC le nang le likarolo tse peli, le sebelisetsoang ho thibela ho phunyeha ka merero e fapaneng, joalo ka matangoana, ho cheka oli le matša a letsoai, 'me e na le bophelo bo bolelele ba tšebeletso ho feta li-geomembrane tsa setso 'me e sebetsa haholoanyane.

Sehlahisoa Tšobotsi

◈ Corrosion resistance.

◈ E bobebe ebile e matla haholo.

◈ Lintho tse thibelang ho senya

◈ Ho hanyetsa mollo

◈ Ho hanyetsa ho phutha

◈ Litlhaku tsohle li fumaneha ka mefuta e ikhethileng ho latela maemo a fapaneng a ts'ebeliso.

Molemo oa Sehlahisoa

Thepa e entsoe e le sebopeho sa mekato e mehlano se ipapisitseng le semelo sa ts'ebeliso le litlhoko tsa moralo oa projeke:

Lera la pele ke lisebelisoa tse khethehileng tsa skeleton.

U sebelisa lisebelisoa tse khethehileng tsa skeleton, lisebelisoa tsa skeleton li sebelisa lisebelisoa tse khethehileng tsa fiber e le skeleton ea lesela la mocha. Fiber e na le likarolo tse latelang:

1. High modulus, shrinkage e tlase haholo

2. Khanyetso e babatsehang ea kutu;

3. Boima, matla a phahameng, a lekanang le matla a terata ea tšepe karolong e le 'ngoe, empa ke 1/7 feela boima ba pipe ea tšepe;

4. Li-anti-wicking, tse thibelang ka katleho hore metsi a se ke a kenella ka har'a thepa le ho baka tšenyo ho eona.

5. Khanyetso e phahameng ea ho phutha.

Tšebeliso ea sebopeho se khethehileng se lohiloeng se rarolla shrinkage ea longitudinal linear ea thepa, e fetohang katoloso ea molumo ka tataiso ea botenya. Ho ea ka tlhahlobo ea k'hamphani ea rona, ho -25 ℃, ha ho na phetoho ka boholo ba lihora tse 25, 'me ho 80 ℃ bakeng sa lihora tse 168, ha ho na phetoho ea boholo ba geometri.

Ka lebaka la matla a phahameng a lisebelisoa tsa skeleton, e ka hanyetsa ka ho feletseng ho senyeha le khatello ea kelello ea thepa ea polasetiki ea holim'a metsi.

Likarolo tsa bobeli le tsa boraro: moralo oa lera le khethehileng la tlamahano

Theknoloji ea ho khomarela ke theknoloji ea ho hokahanya bokaholimo ba lintho tse homogeneous kapa tse sa tšoaneng hammoho le sekhomaretsi. Lisebelisoa li na le kamano 'me li theha kakaretso.

Mokhahlelo oa bone le oa bohlano: moralo oa lisebelisuoa tse thibelang kutu le tse thibelang likhohlano

1. Ho kenyelletsoa ha lisebelisoa tse tsoang linaheng tse ling tse khahlanong le li-ultraviolet ho ka fokotsa haholo tšusumetso ea mahlaseli a ultraviolet ho tsofala ha thepa. Sehlahisoa se monya mahlaseli a ultraviolet ka matla (haholo-holo bolelele ba 290-400nm) 'me se sireletsa lipolasetiki ho senyeha ha photo-oxidative ho bakoang ke mahlaseli a ultraviolet, ka hona ho lelefatsa bophelo ba tšebeletso ea sehlahisoa haholo le ho matlafatsa ho hanyetsa boemo ba leholimo le ho hanyetsa botsofali ba sehlahisoa.

E le ho fihlela litlhoko tsa ho hanyetsa botsofali ba polasetiki, k'hamphani ea rona e tla eketsa li-stabilizers tse khanyang, li-absorber tsa ultraviolet, le li-plasticizers tse thibelang serame ho foromo e le ho finyella litlhoko tsa bareki.

2. Tšebeliso ea li-modifiers tse hanyetsanang le serame tse tsoang linaheng tse ling ho fetola ho phunyeha ha mocheso o tlaase oa thepa e khethehileng ea ho lutla ho ka thibela sehlahisoa hore se se ke sa senyeha tlas'a maemo a tlaase a mocheso. E na le boemo ba leholimo bo botle le ho hanyetsa serame 'me e boloka sehlahisoa se le ho -20-50°C. toughness babatsehang, matla a tšusumetso, le khatello ea kelello crack resistance.

3. Hlahisa lisebelisoa tse fetotsoeng ka ntle ho naha ho matlafatsa khanyetso ea ho bola ea lik'hemik'hale ea lisebelisoa tse khethehileng tse thibelang ho senya; likarolo tse ka sehloohong tsa brine ke: cations Na+, Ca+, Sr2+; anions Cl-, SO42-,Br-, HCO3-, thepa e sebelisoang k'hamphaning ea rona. Har'a bona, ha ho le e 'ngoe ea lisebelisoa tse tala tse tla itšoara ka' mele kapa lik'hemik'hale ka likarolo tse ka har'a brine, 'me lisebelisoa tse sebelisoang kaofela li inert.

4. Hlahisa lisebelisoa tse sebetsang tse tsoang linaheng tse ling ho matlafatsa ho hanyetsa ho phunya, ho apara ho hanyetsa, ho hanyetsa ho feto-fetoha ha maemo, ho thatafatsa, ho beha khatello e ntle, le ho hlaphoheloa ha lisebelisoa tse khethehileng tse khahlanong le ho lutla, e le hore thepa e be le melemo ea rabara ka nako e le 'ngoe. Ts'ebetso e ntle ho feta ea rabara.

Tšebeliso ea litharollo tse ka holimo tsa moralo ha e rarolle feela tšenyo ea thepa ka ho bola ha lik'hemik'hale, empa hape e sebelisa ka masene sebopeho sa li-multi-layer ho rarolla deformation le puncture resistance ea thepa. Moralo o rarolla bothata ba deformation ea mocheso lintho tse bonahalang chenchana e le hore ho tjheseletsa seam ho hloleha ha lintho tse bonahalang e rarolloa ka tsela e khotsofatsang. Melao-motheo e ka holimo ea moralo e netefalitsoe ka ts'ebetso hore e ka khonahala ebile e fetoha le maemo haholo. Litšobotsi tsa sehlahisoa sena li kopantsoe ka mokhoa o hlophisitsoeng le thepa e ikhethang ea lisebelisoa tse sa tšoaneng ho theha thepa e khethehileng ea anti-seepage composite. Mehaho eohle ea mekhahlelo e mehlano e entsoe ka mokhoa o phahameng oa mocheso oa mocheso o chesang ho etsa hore ho be le kakaretso. Le hoja sehlahisoa se qetella se entsoe ka kakaretso, karolo e 'ngoe le e' ngoe e sebetsang e na le karohano ea eona ea mosebetsi le karolo ea eona, e etsa hore ho be le phello e akaretsang ea synergistic ho etsa bonnete ba hore thepa e khahlanong le ho lutla le ho apara, ho hanyetsa boemo ba leholimo, deformation e nyenyane le thepa e meng.